Paper Machine Roll Bearing Protection

Permanent Bearing Protection Leads to Increased Reliability

The Importance of Bearing Protection

Bearings are designed to operate for many years, yet, they commonly fail due to the high humidity and heavy washdown environments found in paper mills. Contamination, such as water or dirt, entering the bearing housing or lubrication escaping are two of the most common reasons for premature bearing failure. This leads to unexpected downtime and high maintenance costs.

The High Cost of Contact Seals

Contact seals, such as lip seals, are commonly used on rotating equipment to seal the bearing housing. Yet, due to their contacting nature, they wear at the point of contact or groove the shaft, rendering them ineffective in a short period of time. This allows lubrication to escape and contamination to enter the bearing housing.

To increase equipment reliability and decrease maintenance costs, protect your paper machine rolls with permanent bearing protection.

A Permanent Sealing Solution

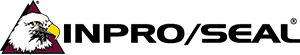

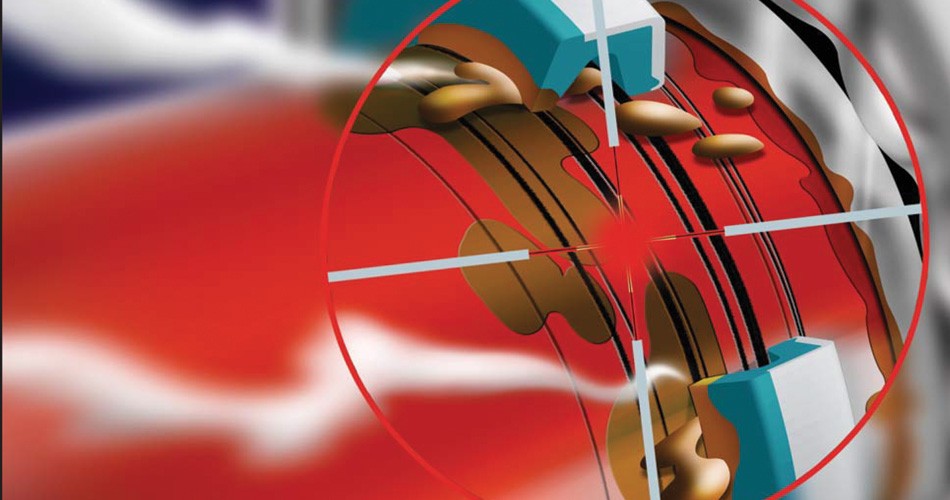

Effectively seal your paper machine rolls with Inpro/Seal Bearing Isolator technology. The Inpro/Seal PMR Bearing Isolator is a compound labyrinth seal specifically developed for use with wet and dry end paper machine rolls. Its innovative non-contacting design prevents catastrophic bearing failure and minimizes unscheduled downtime by permanently protecting bearings against contamination ingress and lubrication loss.

Bearing Isolator Design for Paper Machine Rolls

Facts at a Glance

Inpro/Seal Bearing Isolators on paper machine rolls:

- Permanently protect against contamination ingress from heavy water spray and dust particulates

- Protect against lubrication loss

- Are designed specifically for heavy wash down and high humidity environments

- Are available in split designs for easy installation

- Are custom engineered

- Are backed by our best-in-class performance guarantee

Same-Day Shipments

Inpro/Seal is committed to making sure you have the right technology, right when you need it. We know that time is money. That’s why we offer same-day shipments on most Bearing Isolators, even new and custom designs. If you require same-day shipments on an Inpro/Seal Bearing Isolator, contact your local Inpro/Seal Representative.

Increase Reliability. Decrease Costs.

Inpro/Seal increases reliability and enhances performance on rotating equipment across multiple industries with permanent bearing protection and complete shaft seals. Read more about our innovative technologies or the industries we serve.

Ready to Get Started?

Count on us to improve paper machine roll reliability through permanent bearing protection. With over 40 years of experience, we are the trusted source of Bearing Isolator technology.