Application Success

ROTARY FEEDER

Make: Meyer

Model: 26X26HDX

Industry: Power Generation

Challenge

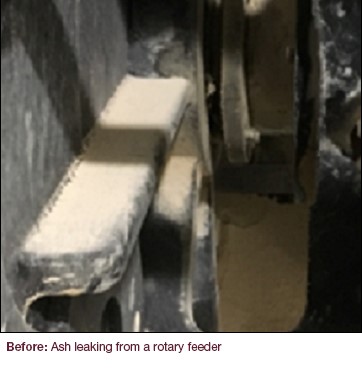

A rotary feeder application in the scrubber area between the ash silo and ash slurry tank constantly leaked ash. This created an environmental and safety concern due to ash coating the environment.

Packing had to be replaced weekly, significantly increasing maintenance costs and downtime. The plant was frustrated and desperate for a solution that worked.

Solution

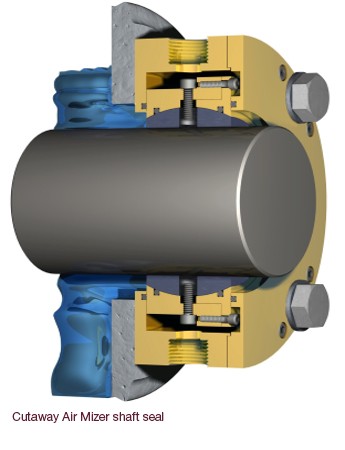

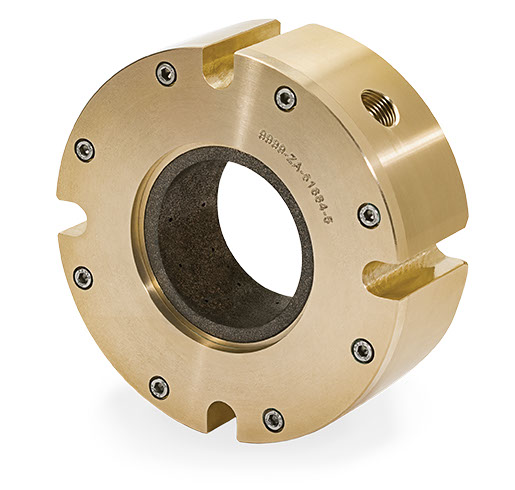

An Inpro/Seal® Air Mizer® shaft seal was installed in July 2018. The Air Mizer seal is a non-contacting, non-wearing shaft seal that uses a positive air purge to permanently eliminate leakage.

Result

The plant stated that success would be measured by a seal that could go one month without leaking. The Inpro/Seal Air Mizer shaft seal has run maintenance free, with zero leakage, since installation.

Maintenance-Free Shaft Sealing

Inpro/Seal Air Mizer shaft seals provide permanent protection against product loss and contamination on industrial process equipment. With a unique, non-wearing design, Air Mizer seals are maintenance-free and constructed to last the lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.