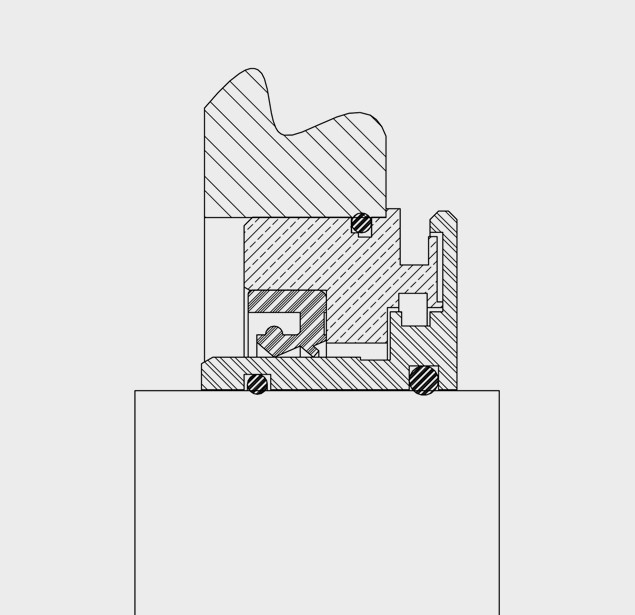

STS Bearing Isolator

A superior sealing solution for applications with flooded shafts.

Applications with flooded shafts, specifically gearboxes and pumps, are some of the most difficult applications to seal. Non-contacting seals cannot effectively seal pressure, allowing oil to leak to atmosphere. Contact seals are the preferred sealing method; however, they lose effectiveness in a short period of time due to wear. Purged seals are another option, but they can be expensive to purchase and maintain.

The Inpro/Seal STS Bearing Isolator effectively seals applications with flooded shafts through innovative design and technology. Its unique design combines a contact seal with Inpro/Seal’s patented XX Interface to protect against contamination ingress and lubrication loss. To increase seal life expectancy, the contact seal rides on an precision stainless steel rotor, creating a consistent sealing surface and decreasing wear.

Technical Data

- Standard Material – Bearing Bronze and 416 Stainless Steel

- Axial Movement – 0.13 mm (0.005 in.)

- Radial Movement – 0.38 mm (0.015 in.)

- Temperature Range – -26°C (-15°F) to 121°C (250°F)

- Pressure – 0.34 bar (5 psi)

- Speed – up to 5,000 sfpm depending on application

- Standard Overall Length – 19.05 mm (0.750 in.), 22.86 mm (0.900 in.)

- Shaft Size – 15.88 mm (0.625 in.) to 381 mm (15.000 in.)

Consult an Inpro/Seal representative for operating conditions outside of limits shown.

Typical Applications

Downloads

Ready to Get Started?

Count on us to improve equipment reliability through permanent bearing protection. With over 40 years of experience, we are the trusted source of Bearing Isolator technology.