Application Success

PILLOW BLOCK

Make: SKF

Model: SNL 3164, 300mm shaft

Industry: Aluminum Smelting

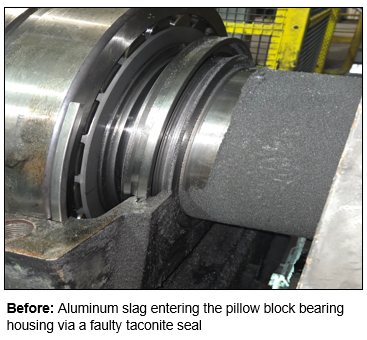

Challenge

In an aluminum plant, ball mills crush and grind aluminum dross (ash or slag), a byproduct of the aluminum smelting and recycling processes, to recover valuable metallic aluminum from this waste material.

On a ball mill in eastern Canada, aluminum dross was leaking into the pillow blocks driving the large 300mm shaft, causing bearing failure and shaft damage. These issues lead to high maintenance costs, interruption in production due to equipment downtime and safety risk.

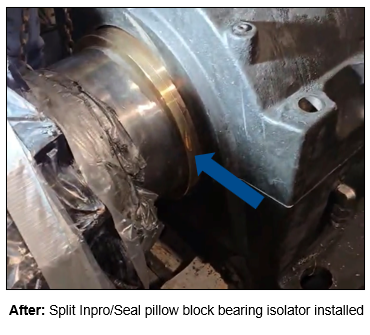

Solution

A split Inpro/Seal® bearing isolator was installed on the pillow block nearest the leaking aluminum dross to eliminate powder ingress into the bearing housing.

Result

Shaft damage and premature bearing failure was eliminated. Because the Pillow block does not need to constantly be removed from failure, downtime and maintenance costs have significantly decreased. Due to the success of this seal, equipment maintenance can now be planned and scheduled, and the customer is currently looking to upgrade all other ball mill pillow blocks.

Permanent Bearing Protection

Inpro/Seal Bearing Isolators provide permanent bearing protection against contamination ingress and lubrication loss on rotating equipment. With a unique, non-contacting design, Inpro/Seal Bearing Isolators are maintenance-free and last lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.