Our History

Falling Windows: The Origin of the Bearing Isolator

In February 1975, David C. Orlowski was working in the pump distribution and repair business when he was called out to repair and retrofit 16 HVAC pumps at Chicago’s Sears Tower.

Even though it was February in Chicago, the south side of the building was supposed to be cooled because of the intense daytime sun load. One of the chilled water pumps had failed, though, resulting in a cooling system failure. The building structure began to suffer and several windows had fallen from the 110-story building onto the street below.

According to Orlowski, “They were refinery pumps with rubber lip seals, which is a rarity. It shouldn’t have been done, but it was. One of the single spring mechanical seals started to spray water and of course the water was coming out of the seal and going right through and under the lip seal, which was worn. It went through there and into the bearing housing, causing bearing failure and a catastrophic wreck.”

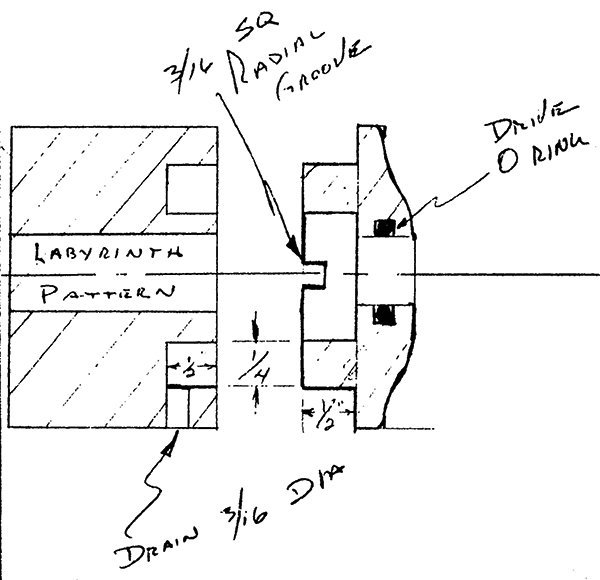

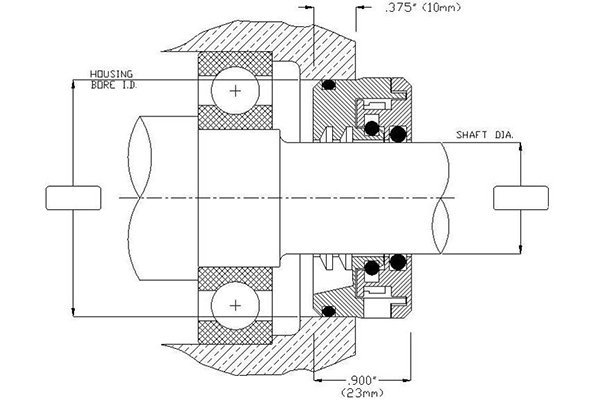

Orlowski and his team retrofitted the API refinery pumps with standard API labyrinth seals, made with a rotor and a stator. Orlowski then turned his attention to solving this issue on process pumps, where rubber lip seals were standard. As he experimented with labyrinth seals, Orlowski started with the challenging application of pumps in the corn processing industry, which were cleaned daily – with a fire hose.

“It took about six months to design something that would work in severe hose-down conditions,” said Orlowski. “We finally found a combination of rotor and stator that would keep oil in, but also ward off contamination up to and including a fire hose. Now we really had an upgrade. It would perform much better than any other labyrinth seals made by pump manufacturers because it would hold off any contamination without contact.”

The first Bearing Isolator was installed in 1975 at the Grain Processing Corporation plant in Muscatine, Iowa, to address a critical issue.

It was the start of an ongoing journey to supply permanent bearing protection to industrial rotating equipment.

David C. Orlowski, 1935-2021

Driving Innovation

Since inventing the original Bearing Isolator in 1977, we have maintained a leadership position through innovative thinking, expert engineering and robust product development.

A Tradition of Innovation

-

1975

-

1990

-

2000

-

2010

-

2020

-

2022

1975

The first Bearing Isolator installation

The first Bearing Isolator is installed on a process pump at the Grain Processing Corporation plant in Muscatine, Iowa.

1977

Orlowski patents the Bearing Isolator

David C. Orlowski is awarded patent protection for the original Bearing Isolator (Patent No. 4,022,479) and coins the term “Bearing Isolator”.

1977

Orlowski founds Inpro/Seal in Rock Island, Illinois.

1991

VBX Bearing Isolator is introduced

The VBX Bearing Isolator introduces the now-standard VBX® Ring for protection against vapor contamination.

1994

Bearing protection requirements for motors are written into IEEE Standard 841.

1998

VBXX Bearing Isolator is launched

The VBXX introduces the now-standard XX Interface to the Inpro/Seal Bearing Isolator design.

2001

VBXX-D Bearing Isolator is introduced

The VBXX-D design utilizes the XX Interface to provide effective contamination exclusion and incorporates a deep D-groove to ensure superior oil retention and return.

2002

Air Mizer® shaft seal is introduced

The articulating Air Mizer shaft seal is a permanent, non-contacting seal that can accommodate radial run-out, axial movement and angular misalignment.

2005

Motor Grounding Seal® is introduced

The Motor Grounding Seal provides a combined Bearing Isolator/shaft grounding solution for VFD-controlled AC motors.

2009

Inpro/Seal is acquired by Waukesha Bearings Corporation and becomes part of Dover

2010

Inpro/Seal establishes manufacturing in Glasgow

Glasgow manufacturing facilitates superior customer service for the European market, including same-day shipments on a majority of part numbers.

2013

Inpro/Seal launches Sentinel® Floating Brush Seal

A drop-in replacement for carbon rings, the Sentinel FBS enhances sealing effectiveness and extends maintenance intervals on process steam turbines.

2014

Launch of Smart Shaft Grounding

Inpro/Seal applies smart condition monitoring technology to shaft grounding rings to alert users in real time to shaft grounding performance.

2014

mini66™ Bearing Isolator is introduced

The mini66 seal becomes the smallest Bearing Isolator available to receive an IP66 rating for protection against water and dust ingress.

2017

VB45-S Bearing Isolator is launched

The VB45-S Bearing Isolator provides IP66 protection against contamination ingress and lubrication loss in a compact design.

2018

Introduction of Dover Precision Components

Inpro/Seal, Waukesha Bearings, Bearings Plus and Cook Compression are unified under the umbrella of Dover Precision Components.

2022

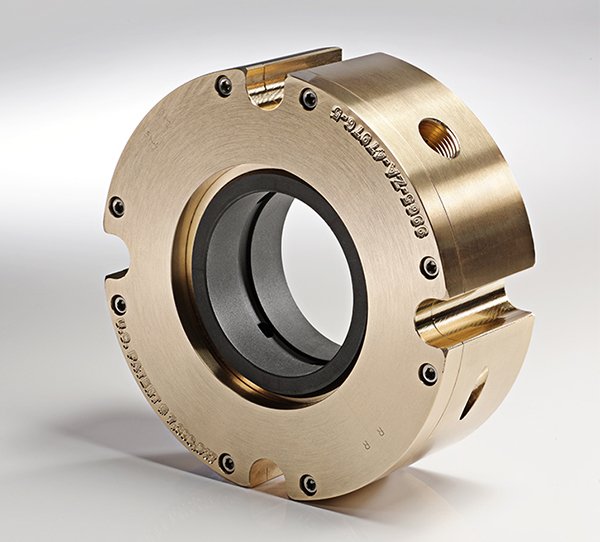

VBMag Bearing Isolator is Developed

The VBMag Bearing Isolator utilizes magnetic force to provide bearing protection in oil mist, high oil splash or flooded bearing conditions.